Industrial Sewage Treatment Plant

Industrial Sewage Treatment Plant Specification

- Treatment Technique

- Clarifier, Biological Treatment, Chemical Treatment, MBR (Membrane Bioreactor)

- Membrane Size

- 8 inch / 4 inch (Standard)

- Power

- 10-50 KW (Depending on Capacity)

- Capacity

- 50 Kiloliter/day

- Application

- Sugar Industry

- Membrane Quantity

- 4-10 (Based on plant design)

- Automation Grade

- Automatic/Semi-Automatic

- Water Source

- Industrial Effluent/Sewage

- Material

- Mild Steel with FRP lining / Stainless Steel (SS304/SS316)

- Ph Level

- 6.5 - 8.5

- Installation Type

- Containerized, Prefabricated, Modular

- Flow Rate

- 50 m/day (can be customized)

- Product Type

- Industrial Sewage Treatment Plant

- Technology

- Advanced Biological Treatment, Membrane Filtration

- Power Source

- Electric

- Operation Type

- Automatic/Semi-Automatic

- Pressure

- 1.5 3.5 kg/cm

- Dimension (L*W*H)

- Custom/As per design specification

- Weight

- Custom as per plant size (Approx. 1-3 Tons)

- Color

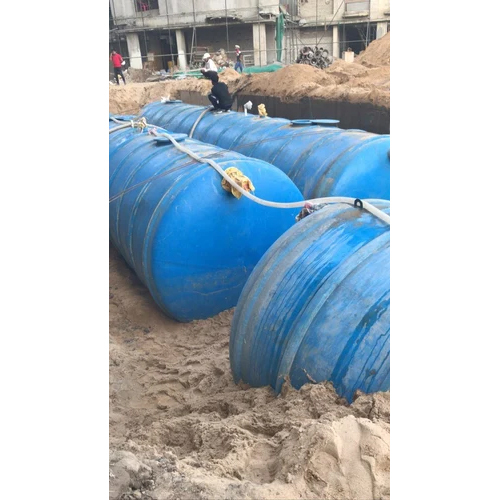

- Blue/Green/Grey (Standard/Custom)

- Warranty

- 1 Year

- Capacity Intel Flow Rate

- 50 m/day

- Inlet BOD (Biological Oxygen Demand)

- Up to 400 mg/L

- Control Panel

- PLC based with HMI

- Service & Support

- Onsite Installation & Technical Support

- Accessories

- All necessary pumps, blowers, piping, and instrumentation included

- Ambient Temperature Range

- 5°C to 50°C

- Treated Water BOD

- Less than 10 mg/L

- Discharge Standards

- CPCB Norms Compliant

- TSS (Total Suspended Solids) Removal Efficiency

- Up to 95%

- Cleaning System

- Automatic Membrane Cleaning in place (CIP)

- Effluent Discharge Type

- Suitable for Reuse or Safe Disposal

- Noise Level

- Less than 75 dB

- Sludge Handling

- Automatic Sludge Removal

- Voltage

- 380-415 V AC, 3 Phase, 50 Hz

Industrial Sewage Treatment Plant Trade Information

- Minimum Order Quantity

- 1 , , Liter

- Supply Ability

- 10 Liters Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- Mizoram, Andhra Pradesh, Bihar, Jharkhand, Odisha, Assam, Chhattisgarh, Nagaland, Tripura, West Bengal

About Industrial Sewage Treatment Plant

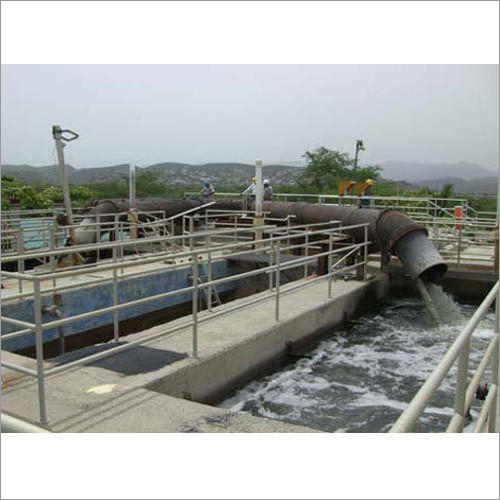

Industrial Sewage Treatment Plant is known for treating wastewater formed by industries. This is used to treat the undesirable by-product. The plant provides good quality reusable water. Its functioning is needed for the protection and welfare of environment. Industrial Sewage Treatment Plant can process the waste included with different chemical components. The plant has good processing and ultimate functionality. The plant is well known for different new projects and boasts of novel technologies such as rainwater harvesting, wastewater treatment, water location transfers, desalination, and others. Feed flow rate is 400 m3/day.

Specification

|

Minimum Order Quantity |

1 Unit |

|

Industry |

Sugar, Chemical, Petroleum Industry, Automobile, etc |

|

Air Blower Power |

1-1.5 kW |

|

Feed Flow Rate |

400 m3/day |

|

Air Blower Count |

2 |

|

Brand |

JRMS |

|

Water Pump Power |

1.5 kW |

|

Voltage required |

380 V |

|

Industry |

Sugar, Chemical, Petroleum Industry, Automobile, etc |

|

Air Blower Power |

1-1.5 kW |

|

Feed Flow Rate |

400 m3/day |

|

Air Blower Count |

2 |

|

Brand |

JRMS |

|

Water Pump Power |

1.5 kW |

|

Voltage required |

380 V |

Advanced Treatment for Industrial Effluents

Leveraging a combination of clarifier, biological, chemical, and advanced membrane treatment, this plant delivers robust performance for industrial sewage, especially in the sugar sector. The integrated MBR system enables consistent achievement of discharge norms, while the automatic membrane CIP ensures stable long-term output quality. The plants modular and containerized design facilitates rapid installation and scalability for diverse site requirements.

Reliable Automation and User-Friendly Control

Equipped with a PLC-based control panel and HMI interface, the plant supports fully automatic or semi-automatic operation. Real-time monitoring, operational customization, and safety alarms simplify usage and reduce manual intervention. Automated sludge handling and cleaning processes further minimize labor needs, enhancing system reliability and consistency.

Complete Service and Support Experience

The solution includes everything required for seamless startup: all pumps, blowers, piping, electricals, and instrumentation. Expert onsite installation, technical support, and a 1-year warranty ensure lasting peace of mind. This plant is built to accommodate custom requirements and is fully compliant with relevant CPCB and industry norms, enabling safe water reuse or environmental discharge.

FAQs of Industrial Sewage Treatment Plant:

Q: How does the Industrial Sewage Treatment Plant achieve consistent compliance with CPCB discharge norms?

A: The plant employs a multi-stage treatment processclarifier, biological, chemical, and advanced MBR (Membrane Bioreactor) technologyto reduce inlet BOD from up to 400 mg/L to less than 10 mg/L, with up to 95% TSS removal. Automated controls, membrane cleaning in place (CIP), and robust instrumentation ensure treated water always meets CPCB standards for safe discharge or reuse.Q: What is the operational process for this sewage treatment plant?

A: Raw industrial effluent first passes through clarification and biological/chemical treatments, effectively reducing organic loads. The MBR system then filters out finer particles, further purifying the water. Automated sludge handling and membrane cleaning keep the system efficient, with the entire process monitored and managed via a PLC-HMI control panel for accuracy and reliability.Q: When is automatic membrane cleaning (CIP) activated, and why is it important?

A: Automatic membrane cleaning in place (CIP) is periodically triggered based on time or detected membrane fouling, as configured via the control panel. Regular cleaning ensures optimal filtration efficiency, prolongs membrane lifespan, and maintains consistent treated water quality, reducing maintenance demands.Q: Where can the treated effluent from this plant be utilized?

A: Treated water produced by this plant meets stringent discharge norms and is suitable for applications such as industrial process reuse, irrigation, or safe environmental disposal, in accordance with CPCB guidelines. The modular, prefabricated design allows installation in varied sugar industry settings across India.Q: How do users benefit from the plants automation and maintenance features?

A: The PLC-based automation reduces operator workload by handling process control, monitoring, and alarm notifications. Automatic sludge removal and membrane cleaning further lower manual intervention, cutting labor costs and ensuring system reliability. Onsite installation and technical support enhance user convenience.Q: What accessories and customization options are provided?

A: Each plant includes all essential pumps, blowers, piping, and instrumentation. Design customization is available for dimensions, membrane quantity, color, and material (Mild Steel with FRP lining or SS304/SS316). Flow rates and capacities can also be tailored to specific industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sewage Treatment Plant Category

50 kld Packaged Sewage Treatment Plant

Minimum Order Quantity : 1 , , Piece

Product Type : Sewage Treatment Plants

Application : Chemical/Petroleum Industry

Material : Mild Steel (with Epoxy Coating)

Color : Blue

FRP Package Sewage Treatment Plant

Price 800000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Sewage Treatment Plants

Application : Industrial

Material : Mild Steel

Color : Blue

Modular sewage treatment plant

Price 400000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Sewage Treatment Plants

Application : Industrial

Material : FRP

Color : Blue

50 KLD Portable Sewage Treatment Plant

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Product Type : Sewage Treatment Plants

Application : Industrial

Material : Iron

Color : Blue

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry